3 Gold Gravity Separation Equipment to Improve the Beneficiation Effect

2022-08-30 Xinhai (2164)

2022-08-30 Xinhai (2164)

If you have any questions, please contact us through the following ways, we will give you more and better assistance!

Gold gravity separation uses the density difference between gold and associated gangue to create separation conditions. With the help of medium fluid, ores of different densities are loosened and layered.

Practice has proved that gravity separation method is an effective and economical treatment method for placer gold. Due to the different particle size composition of gold in placer gold ore, the effective particle size limit of different placer gold beneficiation equipment for processing materials is also different.

Therefore, in the process of gravity separation, in order to enhance the effect of gold separation and improve economic benefits, appropriate gravity separation equipment should be selected.

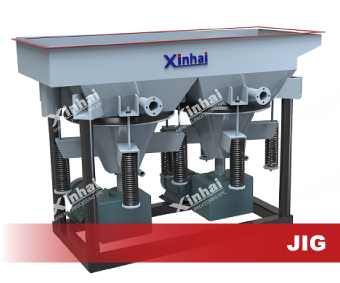

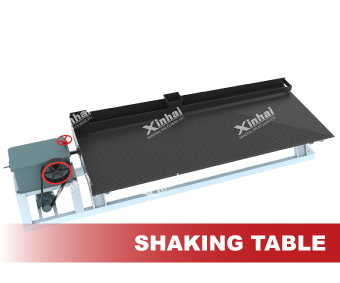

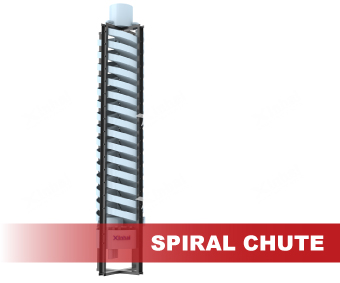

Commonly used gold gravity separation equipment includes jig, shaking table, spiral chute, etc.

The jig will mix the mineral particles of different specific gravity, and stratify according to specific gravity in the variable-speed medium flow of vertical movement. The layered materials are discharged separately.

● The electromagnetic adjustment motor is used for dragging so that the strokes can be adjusted steplessly;

● Large processing capacity and wide selection granularity;

● The operation is simple, and the application effect is very good in roughing gold ore;

● Xinhai jig machine occupies 1/3 less ground than conventional jig machine, and has large processing capacity per unit area.

It is suitable for sorting coarse mineral particles (mineral raw materials of any size except fine materials). For placer gold beneficiation, under the premise that the specific gravity difference is ≥1.25 and the ore monomer is dissociated, the minimum particle size can reach 0.04mm.

Shaking table is a gold mineral processing equipment use in the horizontal medium flow. It mainly uses the transmission mechanism to drive the table surface to do longitudinal reciprocating motion, rush flow and differential motion of the table surface, and the ore particles undergo vertical reciprocation during the reciprocating motion Due to the layering effect of the table surface and the separation effect parallel to the table surface, materials of different particle sizes are discharged from different sections of the table surface to realize sorting.

● Xinhai shaking table has a wide adjustment range of lateral slope (0~10°), and the stroke is easy to adjust;

● The table surface runs smoothly, and the distribution of the ore belt is clearly visible;

● Compact structure and lower energy consumption;

● Rich ore ratio is higher than other mineral processing methods, easy to manage.

According to the particle size of ore, it can be divided into three types: coarse sand table, fine sand table and ore mud table. Among them, the coarse sand table is suitable for sorting gold ore particles with a particle size of 0.5-2.0mm, the fine sand table is suitable for processing gold ore particles with a material particle size range of 0.074-0.5mm, and the slime table is suitable for processing materials with a particle size of 0.074 mm. -0.037mm gold ore grains. In the separation of gold ore, the particle size range of the shaking table is generally between 0.019-3mm, which is suitable for processing and sorting gold minerals with finer particle size.

Spiral chute is a kind of gold mineral processing equipment that uses inclined water flow for sorting. With the help of the combined force of water flow, mineral gravity, and the friction between the ore particles and the bottom of the tank, the ore particles settle in different areas in the tank according to their specific gravity. particles, the sorting is completed.

● Xinhai spiral chute has high efficiency, high recovery rate and accurate ore separation;

● Light weight, anti-rust, wear-resistant, corrosion-resistant, long service life;

● The structure is simple, the processing capacity is large, and the cost is low.

It is suitable for processing fine-grained gold ore with low mud content, and the ore particle size range is 0.03-0.6mm.

The above are the three main gold ore gravity separation equipment, I hope this article can help you choose the appropriate gravity separation equipment. In a beneficiation plant, it is not enough to choose equipment, you also need to know gold beneficiation process. My article How to Extract Gold from Gold Ore will explain different gold beneficiation processes to help you improve the beneficiation effect and get more gold.