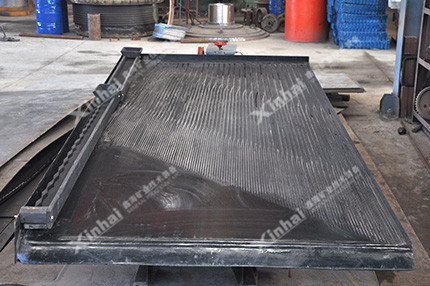

【Product Introduction】:A shaker device that uses the asymmetric reciprocating motion of the bed surface to realize the separation of light and heavy minerals.

【Applicable Materials】:Shaking equipment can be used for different operations such as roughing, beneficiation, sweeping, etc., to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm), ore mud (-0.074) and other different particle sizes.

【Production Capacity】:0.1~1.8 t/h

【Product Application】:Xinhai beneficiation shaker equipment adopts a cam lever head. The stroke can be adjusted by changing the position of the sliding head on the rocker arm, and the stroke rate is adjusted by the smooth motor pulley.

Xinhai shaker has a wide adjustment range of lateral slope, and the stroke is easy to adjust;

The bed surface is flat, has good corrosion resistance, strong and durable, and is convenient for partial repair;

The spring is placed in the case and has a compact structure;

The bedside mechanism is reliable in operation, has few easy to wear parts, does not leak oil, and has advantages such as low power consumption.

Mineral particles are fed into the ore trough at the corner of the shaker bed, and at the same time, horizontal flushing water is supplied from the water feed trough, so the ore particles are in the gravity, the lateral flow of water impulse, the inertia and the inertia generated by the reciprocating asymmetrical movement of the bed surface Under the action of friction, it is layered according to specific gravity and particle size, and moves longitudinally along the bed surface and laterally along the inclined bed surface. The ore particles with different specific gravity and particle size gradually fan out along their respective moving directions, and are discharged from different areas on the concentrate end and tailings side of the shaker, and finally divided into concentrate, medium ore and tailings.

1. Large pulley: stop and check to turn the large pulley by hand. If there is a gap in the large pulley, it means that the large pulley is not installed securely, which will easily produce abnormal noise in actual production.

Solution: Find a piece of discarded hacksaw skin or a thinner iron skin, stuff it into the key of the big pulley (commonly known as the pin), then tighten the fixing screw next to it, and then check whether the gap is eliminated.

2. Rocking lever: stop and check, first remove the two toggle plates next to it, use one hand to stabilize the large pulley first, and swing the rocking lever with the other hand. Under normal circumstances, it can only swing left and right. , The front and back cannot be swayed. If the opposite is the case, the rocking rod is not fixed. In this case, it is not easy to produce abnormal noise during production.

Solution: Tighten the fixing screw on the rocking lever of the 6s shaker

| Model | Coarse sand bed surface | Fine sand bed surface | Slotted bed surface |

|---|---|---|---|

| Bed size (mm) | 4436X1825X1536 | ||

| Stroke (mm) | 16~22 | 10~16 | 10~16 |

| Stroke times (r/min) | 240~290 | 300~320 | 330~340 |

| Water consumption (t/h) | 190 | 80 | 50 |

| Processing capacity (t/h) | 30 | 8 | 8 |

| Feeding size (mm) | 2~0.2 | 0.5 ~0.037 | 0.074~0.019 |

| Supply concentration (%) | 20~25 | 15~20 | 15~20 |

| Minimum installation slope (° ) | 2°30″ | 1°50″ | 0°45″ |

| Dimensions (mm) | 5454X1825X1242 | ||

| Adjustable range of stroke (mm) | 8~22 | ||

| Power (kW) | 1.5 | ||

| Weight (kg) | 1012 | ||

A gravity separation equipment that uses different sedimentation speeds of minerals in vertical alternating currents to realize the separation of light and heavy minerals.

A shaker device that uses the asymmetric reciprocating motion of the bed surface to realize the separation of light and heavy minerals.

A gravity separation equipment of separating minerals with different weight by the inertial centrifugal force generated in the spiral motion of pulp.