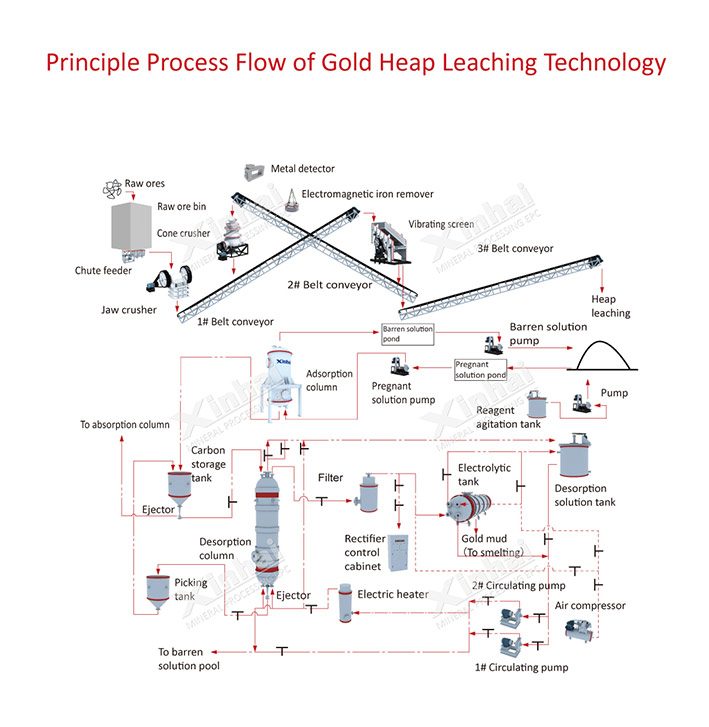

【Process Introduction】:The gold ore heap leaching process is to crush low-grade gold ore to a certain size (or granulate), and pile it on a leak-proof bottom mat paved with materials such as asphalt, concrete or plastic, and use low-concentration cyanide, alkaline solution, Solutions such as non-toxic solvents or dilute sulfuric acid are sprayed on the ore pile to dissolve the gold, and the gold-containing solution is infiltrated from the ore pile, and then the gold is recovered by methods such as activated carbon adsorption or zinc powder replacement precipitation.

【Application Scope】:Heap leaching gold from gold mines is often used to develop gold mines with small ore bodies or low grades, or both, and deposits that cannot be developed and utilized by conventional methods.

The requirements for terrain conditions are not high, and measures can be adapted to local conditions, and permanent unloading yards or stacking yards can be set up according to the characteristics of the terrain. For example, the tops and slopes of hills are relatively gentle and open, so they are suitable for building permanent dumping yards.

The raw ore is crushed to a certain particle size (30-50mm) by the jaw crusher and cone crusher produced by Xinhai, and then goes directly to the heap ; Or carry out granulation treatment (agglomerate finer particles into coarse powder agglomerates), and then transport the ore by forklift to the mine pile for stacking.

Set up a pile leaching system on the paved ore pile. After the cyanide solution reacts with the mine pile, the gold-containing solution (precious liquid) seeps from the bottom of the mine pile, flows into the precious liquid pool, and is pumped into the adsorption column by the precious liquid pump. Reuse of the shower system.

The overall picture of the system in the Tanzania Gold Mine Project of Xinhai Mining. The desorption electrolysis device of this project is one of the core equipment of the "all-slime cyanide gold extraction" program. The desorption electrolysis system adds cations that are easily adsorbed by activated carbon into the desorption body to replace Au(CN)2- to realize gold The precious liquid obtained by desorption of gold-loaded carbon is recovered by ionization method to obtain solid gold.

The Energy Saving Ball Mill is a high-efficiency and energy-saving grid-type ball mill that uses rolling bearings.

Xinhai leaching mixing tank is a cyanide leaching mixing equipment designed with reference to American technology.

Desorption electrolysis system as obtains gold mud from carbon by desorption and electrowinning