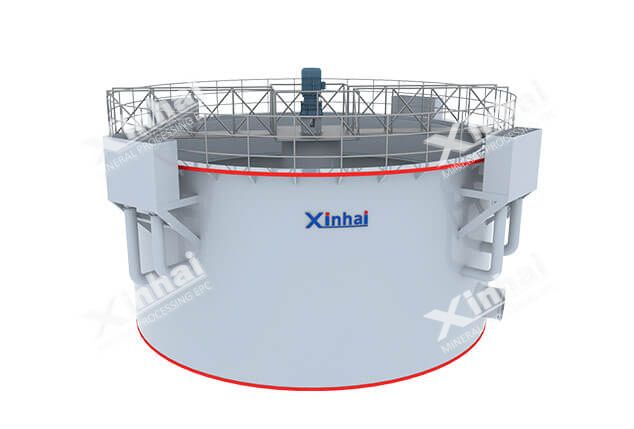

【Product Introduction】:Xinhai leaching mixing tank is a cyanide leaching mixing equipment designed with reference to American technology.

【Applicable Materials】:The double-impeller leaching stirring tank is suitable for gold leaching, adsorption and other mixing operations where the specific gravity is small, the viscosity is low, the settling speed is slow

【Production Capacity】:6-395 m³

【Product Application】:Double-layer impeller, mixing uniformly, low energy consumption; impeller encapsulated, long service life; using multi-point air supply, uniform aeration.

The ore flow moves smoothly, the ore slurry is evenly mixed, and the power consumption is low;

The air enters the groove through the hollow shaft of the transmission, and is agitated by the blades, and the air is evenly dispersed;

Compact structure and convenient maintenance;

The hollow shaft is ventilated to the bottom, and the air enters the groove through it, which is evenly dispersed and small bubbles;

Using two new impellers, the impeller of the stirring tank is large in diameter, low in speed, and low in stirring power consumption, which can reduce the wear of carbon;

The stirring intensity is moderate, and the slurry concentration and fineness distribution in the tank are consistent, which can improve the leaching rate of cyanidation and the adsorption rate of carbon;

The impeller of the leaching mixing tank is lined with wear-resistant rubber, which has a low speed and a long service life.

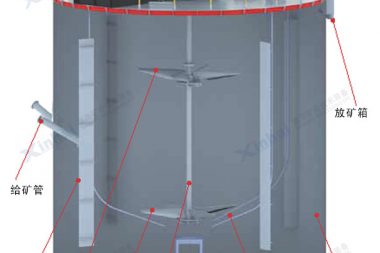

Xinhai double-impeller leaching agitation tank slurry flows from top to bottom in the center under the drag and stirring action of the double-impeller, diffuses through the surrounding damping plate, and feeds air at the lower end of the shaft to mix with the slurry And circulate upwards to form a uniform suspension mixture.

A gold mine in Shaanxi established a beneficiation plant with a daily processing capacity of 200t/d in 2010, using a direct cyanide-zinc powder replacement process. Because the previously installed double-impeller stirring tank stirring blades are slightly smaller, the speed is low, and the slurry is stirred unevenly, which is not conducive to the leaching of gold. Later, Xinhai Mining Equipment Co., Ltd. was contacted to contract the cyanidation process. The Xinhai retrofit equipment uses a slightly larger stirring blade, and is equipped with an anti-back-suction device at the bottom of the hollow shaft. Due to the good ventilation in the center and the uniform stirring of sodium cyanide, a major breakthrough in increasing the leaching rate of gold from 94.28% to 97.14% was achieved

| Model | Trough specification (diameter X height) (mm) | effective volume (m3) | Impeller speed (r/min) | Impeller diameter (mm) | Motor Model |

Motor power (kW) | Model of reducer | Tank weight (kg) | Total weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 909 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 935 | Y112M-4 | 4 | XLD4-5-35 | 2159 | 2729 |

| SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 935 | Y100L1-4 | 2.2 | XLD2.2-4-29 | 2398 | 3095 |

| SJ3.0X3.0 | 3000 X3000 | 19 | 43 | 1130 | Y112M-4 | 4 | XLD4-5-35 | 3480 | 4583 |

| SJ3X3.15 | 3000X3150 | 20 | 3480 | 4160.6 | |||||

| SJ3X3.5 | 3000X3500 | 22.97 | 3211 | 4334.6 | |||||

| SJ3.15X3.55 | 3150X3550 | 25.73 | 1260 | 3433.5 | 4322.8 | ||||

| SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 1310 | Y132S-4 | 5.5 | XLD5.5-5-29 | 3480 | 5025 |

| SJ3.5X4 | 3500X4000 | 35.6 | 4230 | 5429 | |||||

| SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | Y112M-4 | 4 | XLD4-5-35 | 4260 | 5025 | |

| SJ3.7X4.2 | 3700X4200 | 42 | 42 | XLD4-5-43 | 5266 | 6153 | |||

| SJ4.0X4.5 | 4000 X4500 | 52.78 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 6397 | 7569 |

| SJ4.0X6 | 4000 X6000 | 71 | 33 | 1750 | Y160M-4 | 11 | GRF137-Y11- 4P-44.65-M4 |

7681 | 9200 |

| SJ4.5X5.0 | 4500 X5000 | 74.75 | 35 | 1750 | Y132M-4 | 7.5 | XLD7.5-7-43 | 8614 | 10864 |

| SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 2046 | Y160M-4 | 11 | XLD11-8-47 | 8740 | 14291 |

| SJ5.5X6.0 | 5500 X6000 | 135.42 | 2100 | 12467 | 18745 | ||||

| SJ6.5X7.0 | 6500 X7000 | 215 | 21 | 2400 | Y180L-4 | 22 | GRF147-Y22- 4P-70.87 |

17890 | 25978 |

| SJ7.0X7.5 | 7000 X7500 | 269 | 2400 | Y200L2-6 | 22 | XLD22-10-47 | 20505 | 29030 | |

| SJ7.5X8.0 | 7500 X8000 | 331 | 23 | 2900 | Y200L2-6 | 22 | BLD7-43-22L | 22552 | 32796 |

| SJ8.0X8.5 | 8000X8500 | 402 | 18.5 | 3200 | Y250M-8 | 30 | TPS315-3F | 30559.5 | 42467.3 |

| SJ8.5X9.0 | 8500X9000 | 480 | 18.5 | 3300 | Y250M-8 | 30 | TPS315-3F | 34130 | 46623 |

Xinhai leaching mixing tank is a cyanide leaching mixing equipment designed with reference to American technology.

Desorption electrolysis system as obtains gold mud from carbon by desorption and electrowinning

A slurry transporting equipment by compressed air

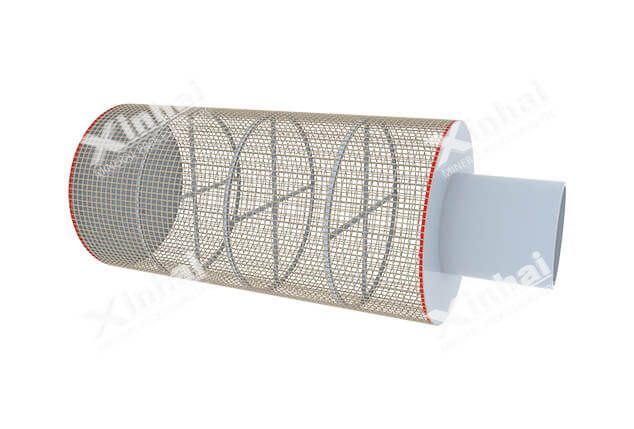

An equipment for separation of carbon and slurry。

Washing thickener for solid-liquid separation of gold leaching liquid

A system extracts gold from pregnant solution by zinc powder