【Product Introduction】:A crusher equipment with high production capacity, large crushing ratio and high crushing efficiency, mainly used for coarse crushing.

【Applicable Materials】:Jaw crushers are widely used in metallurgical mines, building materials, silicate and chemical industries. It is generally used for coarse and medium crushing of hard or medium-hard ore in the beneficiation industry.

【Production Capacity】:0.5~700t/h

【Product Application】:The deep cavity optimized design of the traditional jaw crushers crushing cavity, optimized cavity design, high crushing effect; high rotating speed of the movable jaw and curved jaw plate design, production High ability.

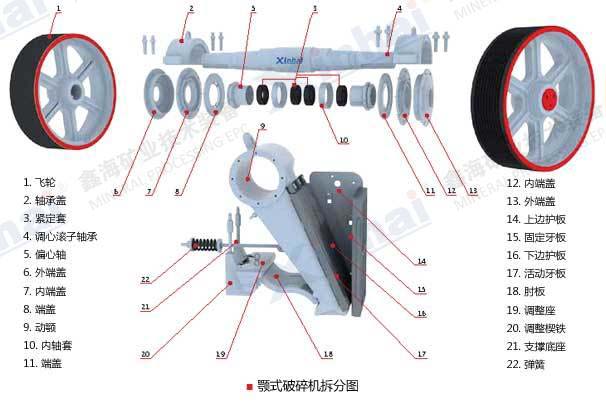

By moving The two jaw plates of the jaw and the static jaw form a crushing cavity, which simulates the movement of the two jaws of an animal to complete the material crushing operation. The upper end of the movable jaw is directly suspended on the eccentric shaft, as the connecting rod of the crank connecting rod mechanism, which is directly driven by the eccentricity of the eccentric shaft, and the underground end of the movable jaw is hinged and supported on the rear wall of the frame with a thrust plate. When the eccentric shaft rotates, the trajectory of each point on the moving jaw is from the circumferential line of the suspension point, gradually turning downward into an ellipse, and the lower part, the more the ellipse is deviated until the trajectory of the connection point between the lower part and the thrust plate is a circular arc String.

n

The movable jaw assembly of the jaw crusher is more advanced, making it more durable;

Deep The cavity crushing ratio is large, the cavity shape is optimized, and the crushing efficiency is high.

The arc-shaped jaw plate design increases the effective length of the jaw plate and increases the processing capacity.

When the jaw crusher is working, when the frame is found to be severely beaten, you should first stop and check several aspects.

1. Whether the bolt is loose or broken

2, whether the position of the flywheel is off-track

3, whether the foundation of the main machine is stable, and whether there are vibration isolation measures< /p>

If the anchor bolt is loose, use a wrench to tighten the bolt. If the anchor bolt breaks, you need to replace it with a new one. bolt.

The solution to the deviation of the flywheel position is to remove the flywheel cover, loosen the flywheel tightening bolts, adjust the position of the flywheel and then tighten the flywheel tensioning sleeve bolt.

If the jaw crusher shakes severely due to the unstable host, the foundation should be reinforced, and sleepers or rubber strips should be added between the machine and the ground

| Type | Model | Inlet size (mm) | Discharge size (mm) | Maximum feeding size (mm ) | Production capacity (t/h) | Eccentric wheel speed (r/min) | Motor Power (kW) | Dimensions (mm) | Weight (kg) |

| General pass type | PE100X150 | 100X150 | 5?20 | 80 | 0.5~2 | 300 | 2.2 | 525X535X605 | 230 |

| PE150X250 | 150X250 | 10 ?40 | 125 | 2?6 | 300 | 5.5 | 875X745X935 | 1100 | |

| PE200X350 | 200X350 | 10 ?50 | 160 | 6?10 | 300 | 7.5 | 1080X1060X1088 | 1600 | |

| PE250X400 | 250X400 | 20 ?60 | 210 | 8?16 | 300 | 15 | 1108X1090X1392 | 1850 | |

| ZGPE250X400 | 1430X1316X1296 | 2800 | |||||||

| PE250X500 | 250X500 | 20 ?80 | 210 | 13 ?21 | 300 | 18.5 | 1360X1450X1440 | 3100 | |

| ZGPE250X500 | 1425X1420X1417 | 3300 | |||||||

| PE400X600 | 400 X600 | 40?100 | 350 | 14?36 | 275 | 30 | 1650X1748X1520 | 5800 | |

| ZGPE400X600 | 1716X1736X1653 | 6500 | |||||||

| PE500X750 | 500X750 | 50?120 | 400 | 30 ?80 | 250 | 45 | 1900X1876X1821 | 9000 | |

| ZGPE500X750 | 1980X2024X1920 | 12000 | |||||||

| PE600X900 | 600 X900 | 75?200 | 480 | 56?192 | 250 | 75 | 2280X2245X2320 | 18700 | |

| ZGPE600X900 | 2280X2245X2320 | 14500 | |||||||

| ZGPE750X1060 | 750X1060 | 80?235 | 630 | 108?256 | 250 | 90 | 2450X2472X2795 | 28000 | |

| ZGPE900X1200 | 900X1200 | 95?265 | 750 | 186?398 | 200 | 110 | 3335X3182X3025 | 50000 | |

| ZGPE1100X1400 | 1100X1400 | 150?300 | 950 | 250?600 | 193 | 132 | 3900X3040X3875 | 70000 | |

| ZGPE1200X1500 | 1200X1500 | 160?320 | 1000 | 280?700 | 190 | 160 | 3800X3040X4150 | 82000 | |

| 细 碎 型 | PEX150X750 | 150X750 | 10 ?40 | 120 | 8?25 | 320 | 15 | 1210X1572X1045 | 2800 |

| ZGPEX150X750 | 1240X1586X1025 | 3500 | |||||||

| PEX200X1000 | 200 X1000 | 15 ?40 | 160 | 12 ?50 | 330 | 22 | 1860X1385X1200 | 5200 | |

| ZGPEX250X750 | 250X750 | 20 ?60 | 210 | 10 ?45 | 320 | 30 | 1751X1400X1515 | 4900 | |

| PEX250X1000 | 250X 1000 | 20 ?50 | 210 | 15 ?50 | 330 | 30 | 1550X1990X1370 | 6500 | |

| ZGPEX250X1000 | 1650X1958X1460 | 6800 | |||||||

| ZGPEX250X1200 | 250X1200 | 20 ?60 | 210 | 20 ?60 | 320 | 45 | 1650X2170X1465 | 9000 | |

| ZGPEX300X1300 | 300X1300 | 25 ?65 | 250 | 20 ?80 | 330 | 55 | 1980X2456X1740 | 11500 |

A crusher equipment with high production capacity, large crushing ratio and high crushing efficiency, mainly used for coarse crushing.

A single-rotor ring hammer crusher for processing low-hardness and brittle materials.

The spring cone crusher is a medium-to-fine cone crusher equipment. The spring functions as a safety device and affects the crushing force.

The supports at both ends of the cone crusher main shaft, scientific design of crushing chamber, double insurance control of hydraulic and lubricating system.