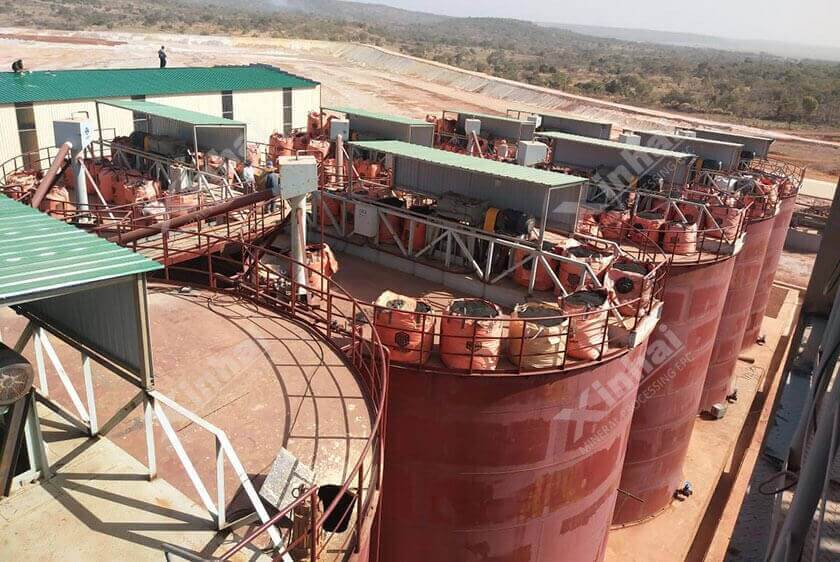

The Guinea 6,000t/d gold mineral processing plant was an EPC+M+O project. The design scope covered construction drawings and workshop drawings and involved engineers in the fields of mineral processing, water supply, and drainage, power, civil engineering, and general layout.

01 In terms of plant design, the design work undertaken by Xinhai included: plant construction drawing design, plant production workshop design of concentrator, which involves various specialties such as dressing, water supply, and drainage, electricity, civil engineering, general drawing, etc.

02 Slurry conditioning of raw ore-grinding and classification-gravity concentration-cyanide leaching-desorption electrolysis.

03 The grinding and classification stage adopted two stages and one closed-circuit grinding process. In the classification stage, slag slurry pump and cyclone were used to replace the spiral classifier, high efficiency, and low investment.

04 The gravity separation stage adopted the jigging machine to separate concentrate.

In line with particular conditions, Xinhai worked to ensure strict compliance with relevant standards, optimize plant layout, minimize costs and shorten construction duration. Thanks to efficient and energy-saving equipment and sound technological process flow, the project received high recognition in the localities.

Wet grid type ball mill is a traditional ball mill that relies on the discharge grid to discharge ore forcibly.

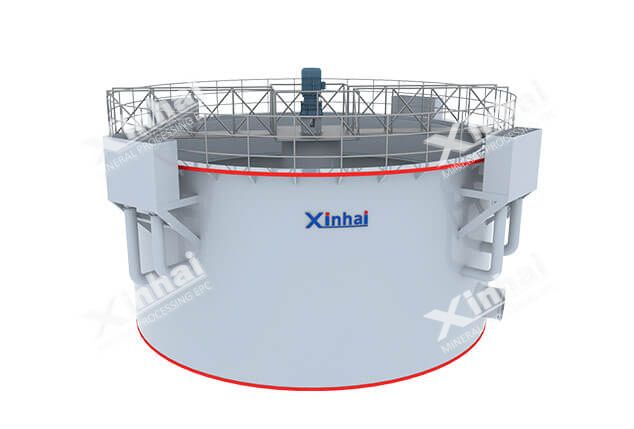

Washing thickener for solid-liquid separation of gold leaching liquid

Xinhai leaching mixing tank is a cyanide leaching mixing equipment designed with reference to American technology.

Desorption electrolysis system as obtains gold mud from carbon by desorption and electrowinning

Xinhaili Hydrocyclone is a kind of involute feeding cyclone with world advanced level.

A gravity separation equipment that uses different sedimentation speeds of minerals in vertical alternating currents to realize the separation of light and heavy minerals.