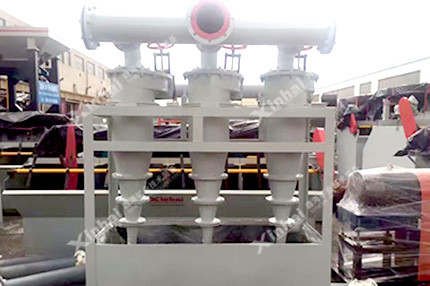

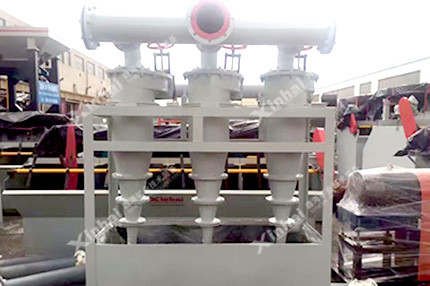

【Product Introduction】:Xinhaili Hydrocyclone is a kind of involute feeding cyclone with world advanced level.

【Applicable Materials】:The working modes of Xinhai Hydrocyclone include: classification, concentration, dehydration, desliming, desander, washing, super-fine grade, etc.

【Production Capacity】:Processing capacity≤542m3/h

【Product Application】:The Xinhaili cyclone adopts an involute feeding method. This involute feeding port is beneficial to increase the centrifugal force of the material, improve the classification effect, and greatly reduce the wear of the feeding box.

The feed port of the hydrocyclone uses involute direction to feed materials, which increases the centrifugal force of the materials, improves the classification effect and greatly reduces the wear of the feed box;

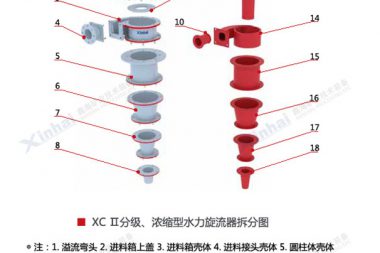

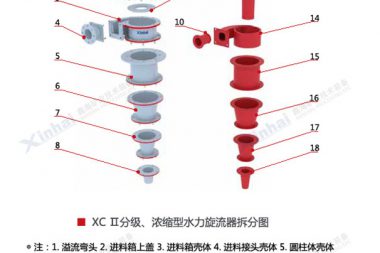

Using the involute method can reduce the turbulence caused by sudden divergence when the material enters the cyclone. The slurry runs smoothly inside the cyclone, thereby improving the separation performance of the cyclone and reducing the feeding of materials. Impact wear of the mine box; The length ratio of the column-cone section of the hydrocyclone and the insertion depth of the overflow pipe are reasonable, and the classification efficiency is higher; With wear-resistant rubber as the inner lining, the service life can be extended by 2-4 times; The structural design is reasonable, the grading index is high, and the index fluctuation is small.

The working principle of Xinhai Hydrocyclone is mainly centrifugal sedimentation. When the two-phase (or three-phase) mixture to be separated enters the cyclone from the feed port of the cyclone at a certain pressure, a strong Three-dimensional elliptical strong rotating shear turbulence motion. Due to the different density of particles, the centrifugal force, centripetal buoyancy force, fluid drag force, etc. are different. Due to centrifugal sedimentation, most of the coarse particles (or heavy phase) are discharged through the bottom outlet of the cyclone, and most of the fine particles ( (Or light phase) is discharged from the overflow pipe, so as to achieve the purpose of separation and classification.

The structure of the Xinhai Hydrocyclone is unique. It adopts a multi-stage column composite structure. The height of the column can be increased or decreased according to needs. If the height is increased, the overflow fineness will increase, up to about 10μm; and each diameter With a unique combination of barrel length and cone angle, the maximum tangential speed can be reached with the smallest total cyclone length, thereby increasing the centrifugal force of the material and improving the classification efficiency.

Hydrocyclone is a commonly used classification equipment in the mineral processing industry. Due to its small footprint, simple structure, easy installation, large processing capacity, and high efficiency of fine particle classification, it is used in mineral processing and classification operations. .

However, the hydrocyclone has a fatal flaw, that is, it is easy to wear.

Xinhai wear-resistant cyclone uses internationally renowned Xinhai wear-resistant rubber as the cyclone lining. Because Xinhai wear-resistant rubber is made with a unique rubber production process of "liquid nano-formulation and high-frequency curing at room temperature", it has stronger wear resistance. The use of Xinhai rubber-lined cyclones can greatly improve the wear resistance of the hydrocyclones, extend the service life, shorten the equipment replacement cycle, increase the equipment operation rate, and reduce the equipment costs.

The feed port of the hydrocyclone uses involute direction to feed materials, which increases the centrifugal force of the materials, improves the classification effect and greatly reduces the wear of the feed box;

Using the involute method can reduce the turbulence caused by sudden divergence when the material enters the cyclone. The slurry runs smoothly inside the cyclone, thereby improving the separation performance of the cyclone and reducing the feeding of materials. Impact wear of the mine box; The length ratio of the column-cone section of the hydrocyclone and the insertion depth of the overflow pipe are reasonable, and the classification efficiency is higher; With wear-resistant rubber as the inner lining, the service life can be extended by 2-4 times; The structural design is reasonable, the grading index is high, and the index fluctuation is small.

The working principle of Xinhai Hydrocyclone is mainly centrifugal sedimentation. When the two-phase (or three-phase) mixture to be separated enters the cyclone from the feed port of the cyclone at a certain pressure, a strong Three-dimensional elliptical strong rotating shear turbulence motion. Due to the different density of particles, the centrifugal force, centripetal buoyancy force, fluid drag force, etc. are different. Due to centrifugal sedimentation, most of the coarse particles (or heavy phase) are discharged through the bottom outlet of the cyclone, and most of the fine particles ( (Or light phase) is discharged from the overflow pipe, so as to achieve the purpose of separation and classification.

The structure of the Xinhai Hydrocyclone is unique. It adopts a multi-stage column composite structure. The height of the column can be increased or decreased according to needs. If the height is increased, the overflow fineness will increase, up to about 10μm; and each diameter With a unique combination of barrel length and cone angle, the maximum tangential speed can be reached with the smallest total cyclone length, thereby increasing the centrifugal force of the material and improving the classification efficiency.

Hydrocyclone is a commonly used classification equipment in the mineral processing industry. Due to its small footprint, simple structure, easy installation, large processing capacity, and high efficiency of fine particle classification, it is used in mineral processing and classification operations. .

However, the hydrocyclone has a fatal flaw, that is, it is easy to wear.

Xinhai wear-resistant cyclone uses internationally renowned Xinhai wear-resistant rubber as the cyclone lining. Because Xinhai wear-resistant rubber is made with a unique rubber production process of "liquid nano-formulation and high-frequency curing at room temperature", it has stronger wear resistance. The use of Xinhai rubber-lined cyclones can greatly improve the wear resistance of the hydrocyclones, extend the service life, shorten the equipment replacement cycle, increase the equipment operation rate, and reduce the equipment costs.

Spiral separator is a device that uses solid particles to settle in the slurry at different speeds for classification.

The submerged classifier is a classifier equipment whose overflow end spiral is completely submerged under the liquid surface.

Xinhaili Hydrocyclone is a kind of involute feeding cyclone with world advanced level.