Very practical! Tungsten ore processing technology

2022-04-18 Xinhai (2125)

2022-04-18 Xinhai (2125)

If you have any questions, please contact us through the following ways, we will give you more and better assistance!

Tungsten has excellent physical, mechanical and chemical properties, so it is widely used in many industries. Commonly used tungsten carbide is used in cemented carbide due to its high hardness, wear resistance and refractoriness; due to its high melting point, it is used in aerospace. And some tungsten compounds are used as lubricants and catalysts. There are many types of tungsten minerals, but wolframite and scheelite are the only ones with real mining and utilization value. Next, this article will introduce the beneficiation methods of wolframite and scheelite.

1 Wolframite separation

Wolframite mining has a high dilution rate. Therefore, the raw ore grade is low, and the ore mineral composition is complex, so the sorting process has certain difficulties. For wolframite or wolframite-based ores, the beneficiation process generally consists of the following parts:

(1) Crushing and discarding waste to obtain qualified ore: It refers to selecting unqualified tungsten ore before the ore is crushed to improve the grade of wolframite.

(2) Discard tailings through gravity separation to obtain coarse concentrate.

(3) The rough concentrate is selected and comprehensively recovered to obtain the final concentrate: there are still many associated minerals in the rough concentrate obtained by gravity separation. The selection operation uses a magnetic separator to separate the associated minerals to obtain qualified wolframite concentrate.

(4) Fine mud treatment: The mineral fine mud produced in the sorting process is concentrated and treated separately.

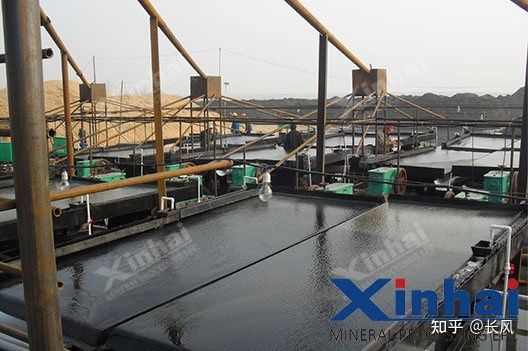

Commonly used equipments in wolframite beneficiation process include rod mill, jigger, shaking table and hydraulic grading box.

2 Scheelite beneficiation

Scheelite can choose gravity separation method, gravity separation + flotation method and single flotation method according to the type of ore embedded.

(1) Coarse grain embedded scheelite —— gravity separation

The density of scheelite is 6.8g/cm3, and the density of gangue minerals such as quartz, feldspar, and calcite is far less than this. Therefore, scheelite can be separated by gravity separation. Commonly used gravity separation equipment includes shaking table, spiral chute, centrifugal concentrator, etc.

(2) Fine grain embedded scheelite —— flotation

Scheelite deposits are often associated with sulfide ores such as molybdenum, copper, bismuth, iron, lead, and zinc. These sulfide ores are naturally more floatable than scheelite and have comprehensive recovery value. The flotation of tungsten ore brings interference, which affects the grade of scheelite concentrate, and the impurities exceed the standard. Therefore, in the process of beneficiation, sulfide ore is generally flotated first and then scheelite.