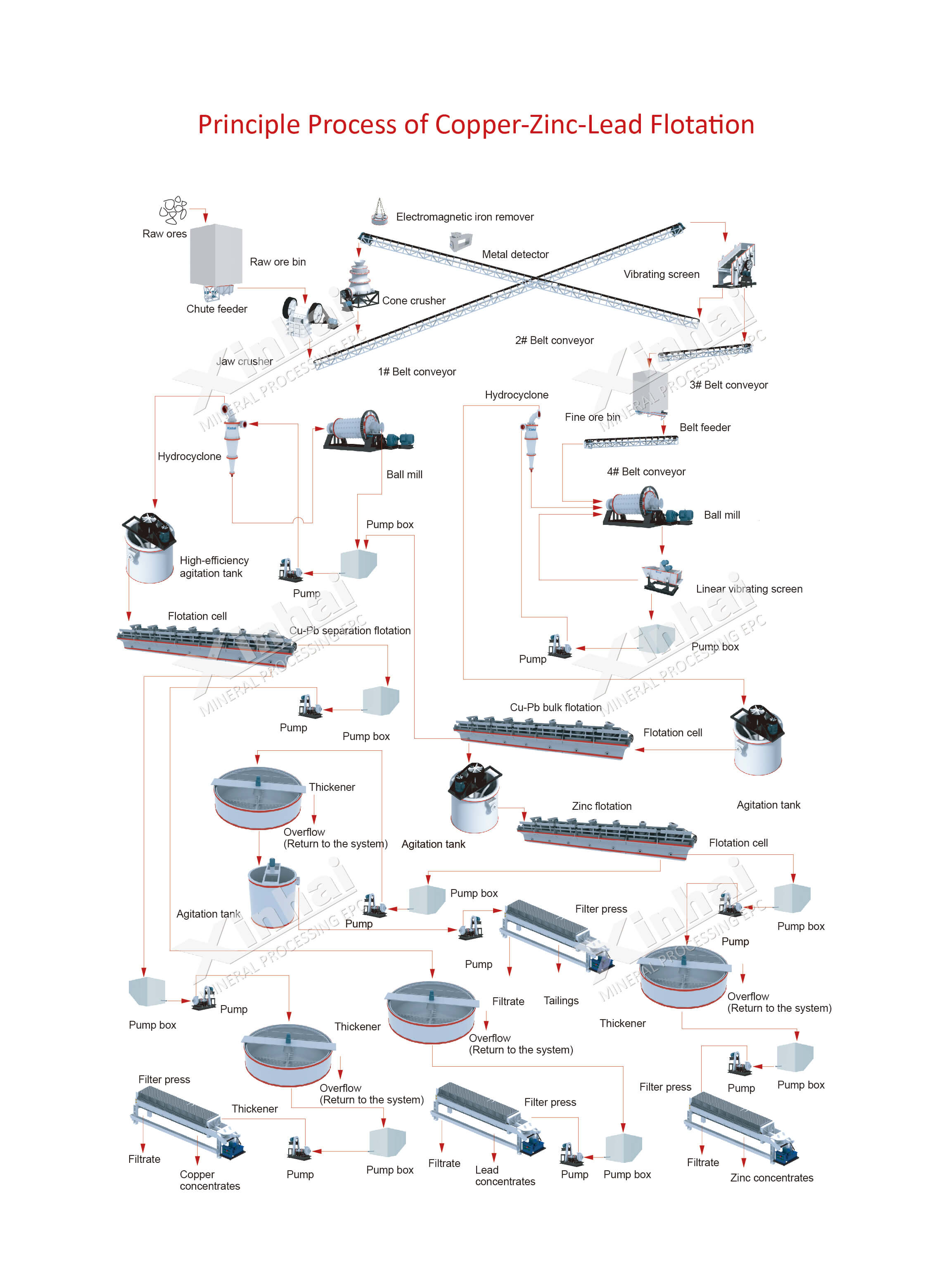

【Process Introduction】:Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic flotation reagents is efficient and environmental protection.

【Application Scope】:Mixed flotation-concentrate regrinding process is applied for Cu-Pb-Zn sulfide ore.

Creative process, low operation cost

Cu-Pb mixed concentrate regrinding process saves the grinding cost without finely grinding all raw ore, and it makes further monomer dissociation to create favorable conditions for the separation of copper and lead.

Strengthen Flotation Process, Increasing Copper Concentrate Grade

In rough flotation, the reagent is carried out strictly to control the reagent amount, realizing early recovery as possible. Reduce multiple recycling and valueless loss. Make the best of foam secondary enrichment, and wash the concentrate foam to reduce the impurities in foams according to suitable water adding.

Copper-Lead Mixed Flotation Separation

In flotation stage, the copper-lead mixed concentrates should be priority separated. After regrinding, the lead concentrates and copper concentrates are separated by flotation and respectively dewatering.

Zinc Flotation Separation

After copper-lead mixed flotation and mixing the slurry, zinc concentrates are separated by flotation from tailings. After dewatering, the zinc concentrate product is required.

Tanzania 150t/d Gold Mineral Processing Plant.The deposit consisted of auriferous quartz veins. Xinhai offered tailored solutions to the project, and crude ingots were produced as final products after smelting.

A traditional slurry Agitation Tank

The BF flotation machine is a self-aspirated mechanical agitation flotation unit with combined slurry suction/non-slurry suction.

Xinhai high-efficiency thickener is a thickener with a brand-new mechanical structure produced by the introduction of American technology.