Process flow of quartz sand extraction from river sand

2023-03-28 Xinhai (2105)

2023-03-28 Xinhai (2105)

If you have any questions, please contact us through the following ways, we will give you more and better assistance!

Quartz sand is widely used in glass manufacturing, semiconductor industry, ceramics and fireproof materials and other industries. Quartz sand is mainly obtained through the extraction of quartz rock and sea sand (river sand). We have introduced the quartz rock beneficiation process many times. to the device.

Sea sand (river sand) is a kind of non-metallic mineral produced by long-term repeated collision and friction under the force of water in the natural state. Its components are relatively complex, and the surface has a certain smoothness. Quartz sand in sea sand (river sand) usually needs to go through the process of scrubbing and desliming-classification-gravity separation-magnetic separation-flotation and acid leaching to complete the extraction of quartz sand. Of course, it is not necessary to go through all the above-mentioned processes, but to choose one or more of them according to the composition of the mineral itself.

Scrubbing and desliming: the purpose of iron removal is achieved by using the mechanical external force of the mechanical scrubber and the collision and friction between the sand particles. The scrubbing efficiency increases with the increase of pulp concentration, which can increase the probability of collision between particles. The placer scrub concentration is better at 50%-60%.

Separation: During the scrubbing process, some impurities such as clay minerals attached to the surface of quartz sand particles will be stripped off to form fine particles mixed in the suspension, increasing the content of fine particles in the product. Because these substances are very fine, it is difficult to achieve complete separation from quartz under the disturbance of the aqueous medium. In order to ensure product quality, separation of target minerals and impurities is required through grading.

Gravity separation: Due to the large difference in density between the heavy minerals in the raw ore and quartz, they can be removed by gravity separation within a similar particle size range.

Magnetic separation: the concentrated ore obtained through gravity separation can reduce the iron oxide content and improve the concentrate grade through magnetic separation.

Acid leaching: Acid leaching uses quartz sand (except HF), and other impurity minerals can be dissolved by acid to complete the purification and purification of quartz sand.

The commonly used equipment for sea sand (river sand) scrubbing and desliming includes rod mills and scrubbing machines.

Rod mill: Use the rod mill to scrub the sea sand (river sand) to improve the purity. The advantage is: the fineness of the finished product of the rod mill is easy to adjust; the rod mill supports dry and wet sand making, unlike Raymond The mill has strict requirements on moisture; the output value of the rod mill has a large span, as small as 0.62 tons, as large as 180 tons per hour, all of which are available for sale, and customers have a wide range of choices.

Scrubbing machine: The scrubbing machine can be said to be a scrubbing equipment specially designed for quartz sand. Commonly used are high-efficiency stirring scrubbing machines and double-helix scrubbing machines. There are 3 impellers on the vertical shaft of the high-efficiency stirring scrubber, which cause the pulp to run in different directions, from top to bottom are down, up and down. When the high-concentration minerals are fed into the ore washing machine together with water from the hopper, the ore pulp is vigorously stirred by the action of three reverse impellers and the baffle installed on the tank wall, and the attachments of lump ore and ore particles in the ore pulp are also automatically The surface is detached and the surface is fully decontaminated. The scrubbed pulp is screened, washed, settled and classified to obtain relatively pure useful minerals.

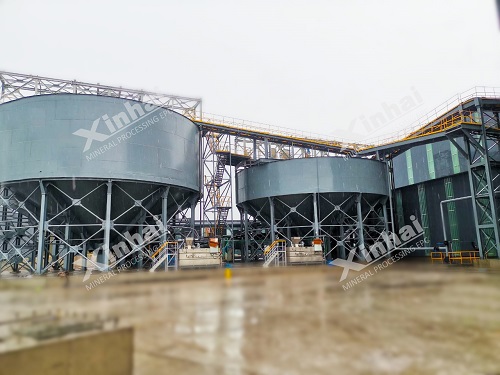

In addition, there are some conventional equipment in the mineral processing plant, such as magnetic separators, flotation machines, re-election jigs, shakers, etc., which are common equipment for extracting quartz sand from sea sand (river sand).

Xinhai can provide you with the process and technology of extracting quartz sand from sea sand (river sand), and can produce a complete set of quartz sand purification equipment. Please contact us if necessary.