How to process lead-zinc ore, You must see!

2022-04-22 Xinhai (2266)

2022-04-22 Xinhai (2266)

If you have any questions, please contact us through the following ways, we will give you more and better assistance!

Lead and zinc are important non-ferrous metals and are widely used in various industries of national economic construction. In nature, lead and zinc coexist very closely. How to process primary lead-zinc ore to obtain lead and zinc? Next, this article will introduce the lead-zinc ore beneficiation process for you.

For the crushing operation of lead-zinc ore, one-stage grinding process or two-stage grinding process can be selected according to the different embedded relationship. One-stage grinding process is suitable for lead-zinc ore with coarse embedded particle size or simple symbiotic relationship; The ore process is suitable for lead-zinc ore with finely embedded particle size or complex symbiotic relationship.

The commonly used equipment for lead-zinc ore grinding is a ball mill, and the classification equipment is a spiral classifier and a hydrocyclone group.

The beneficiation of lead-zinc ore generally adopts flotation method. For different types of lead-zinc ores, different flotation processes such as preferential flotation process, partial mixed flotation process and equal flotation process are used.

1) Priority flotation process: This process is to suppress other minerals, first flotation of one mineral, and then activation and flotation of the second mineral, which is mostly used for lead-zinc-sulfur type ores. In principle, lead is obtained by flotation first. Lead concentrate, then flotation of zinc to obtain zinc concentrate, and finally to flotation of sulfur to obtain sulfur concentrate and discard tailings.

2) Partial mixed flotation process: This process is to suppress the remaining minerals, first flotation of two useful minerals, and then activate and flotation of the third mineral, and the mixed concentrate of the two minerals floated first and then flotation. Separation to obtain qualified concentrate, which is mostly used for copper-lead-zinc type ores, first mixed with copper and lead to obtain copper-lead mixed concentrate, then flotation of zinc to obtain zinc concentrate, and copper-lead mixed concentrate is separated from copper and lead to obtain copper concentrate. mines and lead concentrates.

3) Equal flotation: In this process, the useful minerals in the ore are divided into easy-to-float minerals and hard-to-float minerals according to the different floatability, and then flotation is carried out in the order of easy first and then difficult, and finally the concentrate is obtained. . It is mostly used for complex polymetallic ores, which are easy to float and hard to float.

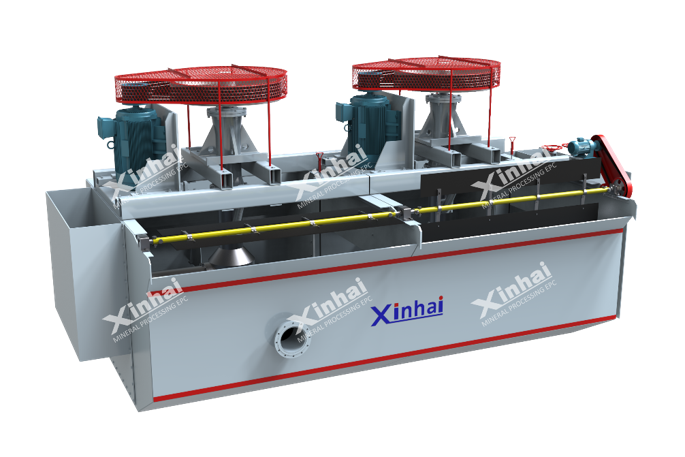

The common equipment for lead-zinc ore separation is flotation cell and high-efficiency Agitation Tank.

The equipment for Dewatering the lead-zinc concentrate products obtained from lead-zinc ore processing includes thickener machine, vacuum filters and filter presses.

The above briefly introduces several beneficiation processes commonly used in lead-zinc ore processing, but the processing technology of lead-zinc ore is not limited to these methods.Which beneficiation method to use needs to be determined by processing test.