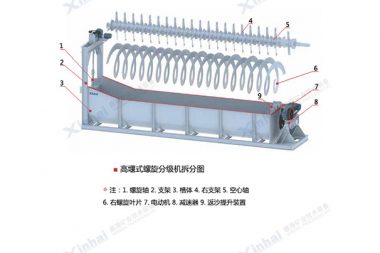

【Product Introduction】:Spiral separator is a device that uses solid particles to settle in the slurry at different speeds for classification.

【Applicable Materials】:The spiral classifier is suitable for coarse grain classification.

【Production Capacity】:10~1785 t/d

【Product Application】:The sand return end of the Xinhai spiral classifier is equipped with an automatic sand return lifting device, which can cancel the configuration of the large spoon head of the ball mill and make the ball mill equipment run more smoothly.

An automatic lifting device for returning sand is added to the sand returning end, which cancels the configuration of the big spoon head of the ball mill;

Each ton of ore can generally save 1 to 1.5 degrees of electricity;

Avoid frequent maintenance of the big spoon head;

Slow down the uneven impact on the large and small gears of the ball mill.

The spiral classifier uses the ground slurry to be fed into the water tank from the feed port located in the middle of the settlement area. Below the inclinedly installed water tank is the slurry classification and settlement area. The spiral rotates at a low speed to stir the slurry. The fine particles are suspended above and flow to the overflow dam to overflow. Coarse particles sink to the bottom of the trough and are conveyed by the screw to the discharge port as returned sand and discharged. The location of the overflow dam is higher than the bearing center at the lower end of the screw shaft and lower than the upper edge of the spiral at the overflow end.

1) Feeding particle size, grinding concentration and mill structure parameters can be better controlled in the automatic control of equipment manufacturing and grinding operations;

2) Grinding media has been greatly improved today when metallurgy and materials have been well developed;

3) The amount of returned sand is related to the classification efficiency, medium filling rate and medium ratio (including the impact of broken balls);

The classification efficiency is mainly affected by the classification concentration, the classification equipment, and the particle size composition of the classification materials, which is difficult to control.

| Type | Model | Spiral speed (r/min) | According to sand processing capacity (t/h) | According to overflow processing capacity (t/h) | Spiral diameter (mm) | Spiral Length (mm) | Sink Slope | Drive Electric Machine model | Drive Electric Machine power (kW) | Boost Electricity Machine model | Boost Electricity Machine power (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single spiral | FLG-300 | 7.7 | 30 ~80 | 10 ~30 | φ300 | 3900 | 14 ~18 | Y100L1-4 | 2.2 | Manual | — | 668 |

| FLG-500 | 8 | 145~260 | 21 ~75 | φ500 | 4390 | Y112M-6 | 1600 | |||||

| FLG-750 | 7.8 | 100~445 | 31~165 | φ750 | 5500 | Y132S-6 | 3 | 2716 | ||||

| FLG-1000 | 6.7 | 473~1026 | 85 | φ1000 | 6556 | Y132M2-6 | 5.5 | 4000 | ||||

| FLG-1200 | 5,6,7 | 1145~1600 | 150 | φ1200 | 6500 | Y132M2-6 | 5.5 | Y90L-4 | 1.5 | 7943 | ||

| FLG-1500 | 2.5,4,6 | 1140~2730 | 235 | φ1500 | 8265 | Y160M-6 | 7.5 | Y100L1-4 | 2.2 | 11827 | ||

| FLG-2000 | 3.6,5.5 | 3240~5940 | 400 | φ2000 | 8700 | Y160L-6/4 | 11,15 | Y100L2-4 | 3 | 20814 | ||

| FLG-2400 | 3.6 | 6800 | 580 | φ2400 | 9130 | Y200L2-6 | 22 | Y112M-4 | 4 | 24194 | ||

| FLG-3000 | 3.2 | 11625 | 890 | φ3000 | 12500 | Y200L-4 | 30 | Y112M-4 | 4 | 42188 | ||

| Double helix | 2FLG-1200 | 5,6,7 | 2290~3200 | 310 | φ1200 | 6500 | Y132M2-6 | 5.5X2 | Y90L1-4 | 1.5X2 | 15840 | |

| 2FLG-1500 | 2.5,4,6 | 2240~5360 | 460 | φ1500 | 8230 | Y160M-6 | 7.5X2 | Y100L1-4 | 2.2X2 | 22903 | ||

| 2FLG-2000 | 3.6,5.5 | 6400~10800 | 750 | φ2000 | 8400 | Y160L-4 | 15X2 | Y100L2-4 | 3.0X2 | 34621 | ||

| 2FLG-2400 | 3.63 | 13600 | 1160 | φ2400 | 9130 | Y200L2-6 | 22X2 | Y112M-4 | 4X2 | 42460 | ||

| 2FLG-3000 | 3.2 | 23300 | 1785 | φ3000 | 12500 | Y200L-4 | 30X2 | Y112M-4 | 4.0X2 | 73030 |

Spiral separator is a device that uses solid particles to settle in the slurry at different speeds for classification.

The submerged classifier is a classifier equipment whose overflow end spiral is completely submerged under the liquid surface.

Xinhaili Hydrocyclone is a kind of involute feeding cyclone with world advanced level.