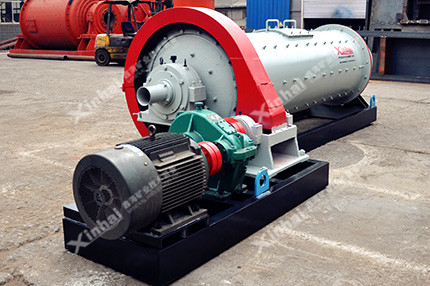

The ball mill is composed of a horizontal cylinder, a hollow shaft for feeding and discharging materials, and a grinding head. The cylinder is a long cylinder with a grinding body inside the cylinder. The cylinder is made of steel plate and is fixed with a steel liner. , The grinding body is generally a steel ball, which is packed into the cylinder according to different diameters and a certain proportion. The grinding body can also be made of steel.

Select according to the particle size of the grinding material. The material is loaded into the cylinder by the hollow shaft at the feed end of the ball mill. When the cylinder of the ball mill rotates, the grinding body is attached to the cylinder due to inertia, centrifugal force and friction. The liner is taken away by the cylinder, and when it is brought to a certain height, it is thrown down due to its own gravity. The falling grinding body crushes the material in the cylinder like a projectile.

Materials from the feeding device through the feeding hollow shaft spirally and uniformly enter the first bin of the mill. The bin has a step liner or a corrugated liner, and various specifications of steel balls are installed. The cylinder rotates to generate centrifugal force to remove the steel balls After being brought to a certain height and falling, it will have a heavy blow and grinding effect on the material. After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition board. The bin is lined with a flat liner and steel balls inside to further grind the material. The powder is discharged through the unloading grate to complete the grinding operation.

The Energy Saving Ball Mill is a high-efficiency and energy-saving grid-type ball mill that uses rolling bearings.

The wet rod mill is a grinding equipment that uses steel rods as grinding media.

Wet grid type ball mill is a traditional ball mill that relies on the discharge grid to discharge ore forcibly.

A ball mill with simple structure and auto-flowing pulp discharge.

An overflow ball mill with rolling bearings, high efficiency and energy saving.

A wet autogenous grinding mill that materials as grinding media