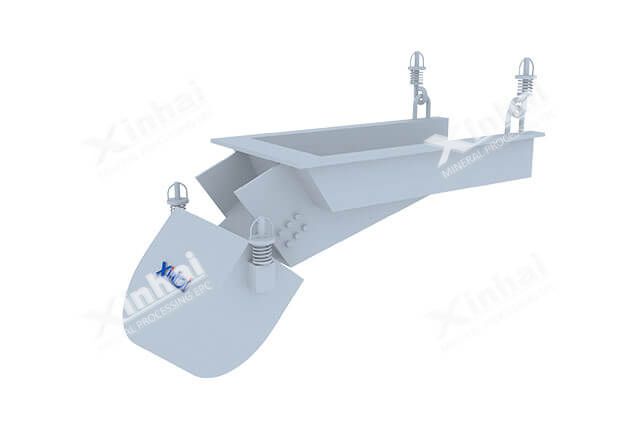

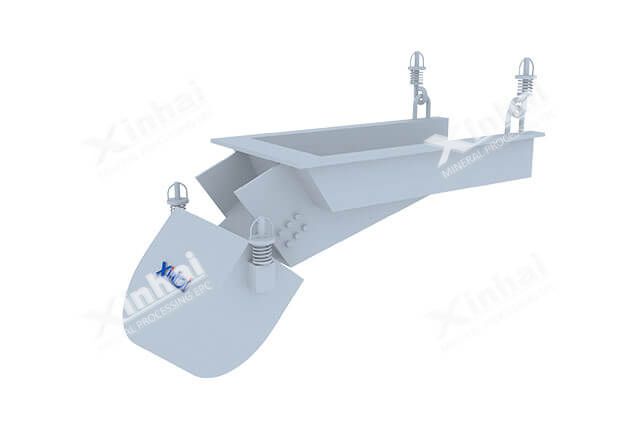

【Product Introduction】:A feeder with simple structure and suitable for non-sticky materials

【Applicable Materials】:It is suitable for high-temperature, severely worn and corrosive materials. It is not suitable for sticky wet powder material or the situation where explosion-proof requirements are required.

【Production Capacity】:7~1700t/h

【Product Application】:It is suitable for high-temperature, severely worn and corrosive materials. It is not suitable for sticky wet powder material or the situation where explosion-proof requirements are required.

01 Small volume, light weight, simple structure, convenient installation, convenient repair, low operation cost;

02 Adoption the principle of the mechanical vibration, and less energy consumption;

03 Change the volume of flow at any time;

04 Centralized control and automatic control of production process;

05 Small wear of feeding tank;

06 Eccentric block is the source of vibration, low noise, less power consumption, good regulation performance, no blanking phenomenon.

The electromagnetic vibrating feeder utilizes an electromagnetic vibrating device to drive minerals to reciprocate in the direction of dip. When the vertical component of accelerated speed of feeder exceeds accelerated speed, minerals are tossed upward and leap forward in a parabolic fashion. It takes 1/5 second to finish the rising and falling. The chute vibrates for one time and subsequently, the minerals are tossed for one time. The chute vibrates at a frequency of 3000/minute. Correspondingly, minerals are tossed upward and has a leap forward. So minerals can continuously and uniformly move forward and feeding is achieved.

| Model | Tank Dimension (LXWXH) (mm) | Feed Size (mm) | Horizontal Feed Amount (t/h) | Feed Amount (t/h) | Power (kW) | Overall Dimension (LXWXH) (mm) | Weight (kg) |

| GZ1 | 600X200X100 | 50 | 5 | 7 | 0.06 | 910X376X485 | 80 |

| GZ2 | 800X300X120 | 10 | 14 | 0.15 | 1175X608X600 | 165.5 | |

| GZ3 | 900X400X150 | 75 | 25 | 35 | 0.2 | 1325X578X675 | 223 |

| GZ4 | 1100X500X200 | 100 | 50 | 70 | 0.45 | 1616X762X814 | 462 |

| GZ5 | 1200X700X250 | 150 | 100 | 140 | 0.65 | 1815X840X980 | 656 |

| GZ6 | 1600X900X250 | 200 | 150 | 210 | 1.5 | 2410X10925X1500 | 1252 |

| GZ7 | 1800X1100X250 | 250 | 250 | 350 | 3 | 2800X1330X1710 | 2017 |

| GZ8 | 2200X1300X300 | 300 | 400 | 560 | 4 | 3302X1556X1995 | 3153 |

| GZ9 | 2400X1500X300 | 350 | 600 | 840 | 5.5 | 3515X1776X2200 | 3750 |

| GZ10 | 2500X1800X375 | 500 | 750 | 1050 | 4X2 | 3630X2500X2235 | 6491 |

| GZ11 | 2800X2000X375 | 1000 | 1400 | 5.5X2 | 4060X2640X2919 | 7680 | |

| GZ12 | 3000X2200X400 | 1200 | 1500 | 15 | 5260X2860X2563 | 8840 | |

| GZ13 | 3200X2500X450 | 1300 | 1600 | 6394X3040X2864 | 9920 | ||

| GZ14 | 3500X2500X450 | 550 | 1500 | 1700 | 18.5 | 7475X3802X3000 | 11000 |

A feeder with simple structure and suitable for non-sticky materials

A feeder with periodic reciprocating motion for fine particles

A mechanical vibrating feeding equipment with rough screening function

A periodic and reciprocating feeding machine for large bulk materials

A feeding machine for short distance transportation.