【Product Introduction】:A traditional and widely used vibrating screening machine, mostly used for medium and fine particle screening.

【Applicable Materials】:Xinhai vibrating screening machine is suitable for the classification of medium and fine particles in mining, coal, metallurgy, building materials, chemical and other departments.

【Production Capacity】:20~300t/h

【Product Application】:The screening equipment adopts wear-resistant rubber to make elastic limit parts; and adopts the company's utility model patented technology: a seat-type vibrating screen jacking device

Xinhai vibrating screen equipment has large amplitude and high screening efficiency;

Abrasion-resistant rubber screen can be provided, and the service life is 10-20 times that of steel and 4-6 times that of polyurethane;

It can provide highly elastic wear-resistant rubber springs with long life, low noise and convenient maintenance; it provides two types of vibrating screens, seat type and hanging type;

There are two types of vibrating screens, seated and suspended;

The large pulley and the eccentric shaft have an eccentricity of 3-5mm, which balances the overall movement of the large pulley when the vibrating screen vibrates and increases the stability of the transmission;

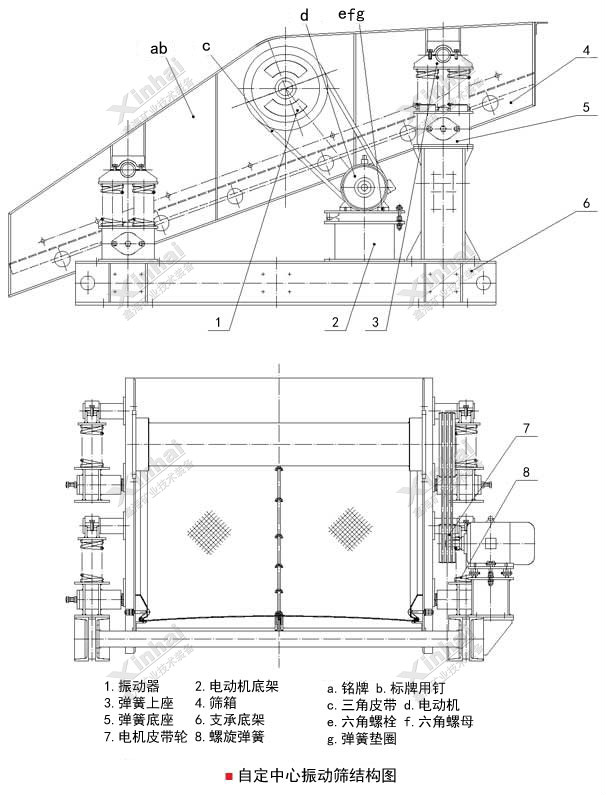

The material on the screen of the self-centering vibrating screen can achieve good looseness and stratification under the action of vibration;

The weight of the vibrating screen can be adjusted, and the amplitude of the screen can be adjusted according to production requirements;

When the amount of ore feed changes, the amplitude also changes. When the amount of ore feed is small, the amplitude increases and the vibration intensifies, and when the amount of ore feed is large, the amplitude becomes smaller. The change of the amount of ore feed will affect the "dynamic balance", which will cause some vibration in the center of the pulley;

Suitable for the screening of medium and fine particles but not for the screening of coarse materials.

The principle of self-centering vibrating screen is that when the motor drives the main bearing of the pulley, the centrifugal inertial force generated is added to the internal force of the screen box vibration system to drive the center of gravity of the screen box system to make a circular movement. The mass of the eccentric weight on the eccentric weight wheel should ensure that the centrifugal inertia force generated by them can balance the centrifugal inertia force generated when the screen box rotates. The condition that the center of the belt pulley does not shift in space is that the centrifugal inertia generated by the rotation of the screen box and the centrifugal inertial force generated by the eccentric weight are equal in magnitude and opposite, and the dynamic balance is reached at this time. In this way, the belt pulley "self-centering" is realized, so that the center distance between the large and small pulleys is kept unchanged, and the phenomenon that the belt is loose and tight is eliminated.

(1) When the sieve machine is running, its vibrating part must not be connected or contacted with any object outside the machine.

(2) When the material is fed, it should be fed in the width direction of the entire screen body at the inlet to ensure the uniform distribution of the material on the screen surface.

(3) When the material falls, there must be no big impact to avoid damage to the screen.

(4) Before starting and stopping, there should be no remaining material on the screen surface.

(5) If there is any abnormal noise during the operation of the equipment, it should be shut down and checked immediately, and the equipment can be turned on only after troubleshooting.

| Model | Specifications | Maximum feeding size (mm) | Processing capacity (t/h) | Motor model | Motor power (kW) | weight | Remarks |

|---|---|---|---|---|---|---|---|

| SZZ0918 | 900×1800 | 40 | 20~25 | Y100L1-4 | 2.2 | 420 | Hanging type |

| SZZ0918 | 900×1800 | 40 | 10~30 | Y100L1-4 | 2.2 | 553 | Seat style |

| 2SZZ0918 | 900×1800 | 40 | 20~40 | Y100L1-4 | 2.2 | 570 | Seat style |

| SZZ1225 | 1250×2500 | 100 | 100 | Y132S-4 | 5.5 | 1017 | Hanging type |

| SZZ1225 | 1250×2500 | 100 | 100 | Y132S-4 | 5.5 | 1466 | Seat style |

| 2SZZ1225 | 1250×2500 | 100 | 100~150 | Y132S-4 | 5.5 | 1320 | Hanging type |

| 2SZZ1225 | 1250×2500 | 100 | 100~150 | Y132S-4 | 5.5 | 1870 | Seat style |

| SZZ1530 | 1500×3000 | 100 | 90~200 | Y132M-4 | 7.5 | 1850 | Hanging type |

| SZZ1530 | 1500×3000 | 100 | 90~200 | Y132M-4 | 7.5 | 2665 | Seat style |

| 2SZZ1530 | 1500×3000 | 100 | 90~200 | Y132M-4 | 7.5 | 2963 | Hanging type |

| SZZ1540 | 1500×4000 | 100 | 90~200 | Y160L-4 | 15 | 2865 | Seat style |

| 2SZZ1540 | 1500×4000 | 400 | 90~200 | Y160L-4 | 15 | 3412 | Seat style |

| SZZ1836 | 1800×3600 | 150 | 100~300 | Y160M-4 | 11 | 4500 | Hanging type |

| 2SZZ1836 | 1800×3600 | 150 | 100~300 | Y160M-4 | 18.5 | 5616 | Seat style |

A mining vibrating screen with advanced performance and circular motion of the screen box.

A vibrating screen in which the screen box reciprocates along a directional straight line, which is mostly used for fine particle screening.

A traditional and widely used vibrating screening machine, mostly used for medium and fine particle screening.