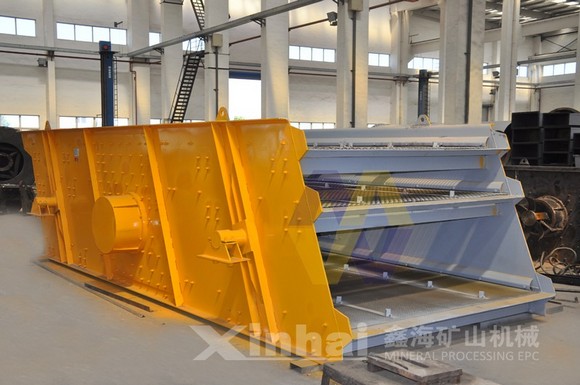

【Product Introduction】:A mining vibrating screen with advanced performance and circular motion of the screen box.

【Applicable Materials】:Copper powder, gold powder, quartz sand, ore, kaolin, etc.

【Production Capacity】:80~1700t/h

【Product Application】:Circular vibrating screen is suitable for material classification in mineral processing, building materials, electric power, chemical industries, etc. It can also be used for dewatering, Desliming, de-intermediation, etc.

The trajectory of circular vibrating screen is close to a circle, so Referred to as circular vibrating screen, it is a new type of multi-layer, high-efficiency vibrating screen;

Using low-stress damping springs, low operating noise;

Using ring groove rivets and plate type The frame structure of the screen box has high strength;

A wear-resistant rubber screen can be provided, which can make the material stuck in the screen hole jump out and prevent the screen hole from being blocked.

The circular vibrating screen adopts a cylindrical eccentric shaft exciter and an offset block to adjust the amplitude. The vibrator is installed on the side plate of the screen box and is The motor is driven to rotate by the V-belt, generating centrifugal inertia force, forcing the screen box to vibrate. The side plate of the screen is made of high-quality steel plate, and the side plate is connected with the beam and the base of the vibration exciter with high-strength bolts or ring-groove rivets. The sieve machine is seat-mounted. The adjustment of the inclination of the screen surface can be achieved by changing the height of the spring support.

Circular vibrating screens are generally installed on the right side of the screen frame, and can also be installed on the left side of the screen frame. If there is no special requirement, the manufacturer installs and supplies the material on the right side of the material movement direction.

(1) The operator should read the duty record before working and conduct a general inspection of the equipment. Check the tension of the V-belt, the oil level in the vibrator, check the tension of the screen surface, the tightening of the bolts of each part, and the damage of the screen surface.

(2) The start of the vibrating screen should follow the sequence of the process system.

(3) When the vibrating screen is working, it is necessary to visually and auditorily check the working conditions of the exciter and the screen box. After the vibrating screen is stopped, touch the vicinity of the bearing cover with your hand to check the temperature rise of the bearing.

(4) The shutdown of the vibrating screen should conform to the sequence of the process system. Except for special requirements, the vibrating screen is strictly forbidden to continue feeding to the screen after stopping with material.

(5) The technical status of the applied vibrating screen and the faults found should be recorded in the duty record when the shift is transferred. The vibration screen record should indicate the damage category of the parts and the date of refilling and changing the oil of the exciter.

Regular inspection of the circular vibrating screen is very important. Workers need to regularly check whether the coarse mesh, fine mesh and spring are fatigued and damaged, and whether various parts of the fuselage are damaged due to vibration, and the parts that need to be lubricated must be lubricated.

< th>Inclination (° )

| Model | Sieve surface | Maximum feeding size ( mm) | Processing capacity (t/h) | Motor | Weight (kg) | |||

|---|---|---|---|---|---|---|---|---|

| Area (m2) | Screen size (mm) | Model | Power (kW) | |||||

| YA1236 | 20 | 6~50 | 200 | 80~240 | Y160M-4 | 11 | 4905 | |

| 2YA1236 | 80~240 | Y160M-4 | 5311 | |||||

| YA1530 | 4.5 | 80~240 | Y160M-4 | 4675 | ||||

| YA1536 | 5.4 | 100~350 | Y160M-4 | 5137 | ||||

| 2YA1536 | 400 | 100~350 | Y160L-4 | 15 | 5624 | |||

| YAH1536 | 30~150 | 160~650 | Y160M-4 | 11 | 5621 | |||

| 2YAH1536 | 30~150; 6~50 | 160~650 | Y160L-4 | 15 | 6045 | |||

| YA1542 | 6.5 | 6~50 | 200 | 110~385 | Y160M-4 | 11 | 5515 | |

| 2YA1542 | 30~150 | 110~385 | Y160L-4 | 15 | 6098 | |||

| YA1548 | 7.2 | 6~50 | 120~420 | Y160L-4 | 5918 | |||

| 2YA1548 | 6~50 | 120~420 | Y160L-4 | 6321 | ||||

| YAH1548 | 7.2 | 30~150 | 400 | 200~780 | Y160L-4 | 6842 | ||

| 2YAH1548 | 7.2 | 30~150 ; 6~50 | 200~780 | Y160L-4 | 7404 | |||

| YA1836 | 6.5 | 30~150 | 200 | 140~220 | Y160M-4 | 11 | 5205 | |

| 2YA1836 | 6.5 | 30~150 | 140~220 | Y160L-4 | 15 | 5946 | ||

| YAH1836 | 6.5 | 30~150 | 400 | 220~910 | Y160M-4 | 11 | 5900 | |

| 2YAH1836 | 6.5 | 30~150; 6~50 | 220~910 | Y160L-4 | 15 | 6353 | ||

| YA1842 | 7.6 | 6 ~150 | 200 | 140~490 | Y160L-4 | 15 | 5829 | |

| 2YA1842 | 7.6 | 6 ~150 | 140~490 | Y160L-4 | 15 | 6437 | ||

| YAH1842 | 7.6 | 30~150 | 400 | 450~800 | Y160L-4 | 15 | 6352 | |

| 2YAH1842 | 7.6 | 30~150; 6~50 | 450~800 | Y160L-4 | 15 | 7037 | ||

| YA1848 | 8.6 | 20 | 6~50 | 200 | 150~525 | Y160L-4 | 15 | 6289 |

| 2YA1848 | 8.6 | 200 | 150~525 | Y160L-4 | 15 | 6624 | ||

| YAH1848 | 8.6 | 30~150 | 400 | 250~1000 | Y160L-4 | 15 | 7122 | |

| 2YAH1848 | 8.6 | 30~150; 6~50 | 400 | 250~1000 | Y160L-4 | 15 | 7740 | |

| YA2148 | 10 | 6~50 | 200 | 180~630 | Y180M-4 | 18.5 | 9033 | |

| 2YA2148 | 10 | 6~50 | 200 | 180~630 | Y180L-4 | 22 | 10532 | |

| YAH2148 | 10 | 13~200 | 400 | 270~1200 | Y180M-4 | 18.5 | 10430 | |

| 2YAH2148 | 10 | 30~150; 6~50 | 400 | 270~1200 | Y180L-4 | 22 | 11190 | |

| YA2160 | 12.6 | 6~80 | 200 | 230~800 | Y180M-4 | 18.5 | 9926 | |

| 2YA2160 | 12.6 | 6~50 | 200 | 230~800 | Y200L-4 | 22 | 11249 | |

| YAH2160 | 12.6 | 30~150 | 400 | 350~1500 | Y200L-4 | 30 | 12490 | |

| 2YAH2160 | 12.6 | 30~150; 6~50 | 400 | 350~1500 | Y200L-4 | 30 | 13858 | |

| YA2448 | 11.5 | 6~50 | 200 | 200~700 | Y180 M -4 | 18.5 | 9834 | |

| YAH2448 | 11.5 | 6~50 | 400 | 310~1300 | Y200L-4 | 30 | 11830 | |

| 2YAH2448 | 11.5 | 30~150; 6~50 | 400 | 310~1300 | Y200L-4 | 30 | 13012 | |

| YA2460 | 14.4 | 6~50 | 200 | 260~780 | Y200L-4 | 30 | 12240 | |

| 2YA2460 | 14.4 | 6~50 | 200 | 260~780 | Y200L-4 | 30 | 13583 | |

| YAH2460 | 14.4 | 30~150 | 400 | 400~1700 | Y200L-4 | 30 | 13096 | |

| 2YAH2460 | 14.4 | 30~150; 6~50 | 400 | 400~1700 | Y200L-4 | 30 | 14455 | |

A mining vibrating screen with advanced performance and circular motion of the screen box.

A vibrating screen in which the screen box reciprocates along a directional straight line, which is mostly used for fine particle screening.

A traditional and widely used vibrating screening machine, mostly used for medium and fine particle screening.