【Product Introduction】:A dewatering equipment that uses the pressure of the slurry pump to make the liquid come out through the filter cloth. It is divided into a box filter press and a plate and frame filter press.

【Applicable Materials】:Xinhai plate and frame filter can be widely used in environmental protection industries such as medicine, chemical industry, standard parts, pharmacy, metallurgy, non-standard screws, dyes, food, brewing, ceramics, oil refining, sewage treatment, etc.

【Production Capacity】:20~1000 ㎡

【Product Application】:The plastic-steel filter plate of the filter press is precision-casted, resistant to high temperature and high pressure, and durable; programmable control, automatic operation.

The equipment has stable performance, high degree of automation, safety and reliability, convenient operation, and can realize backwashing operations.

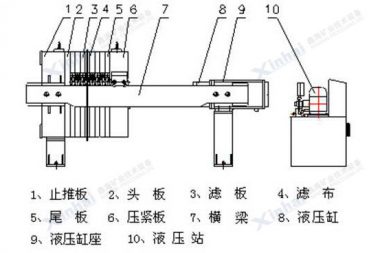

Program-controlled automatic hydraulic box filter press is a kind of intermittent solid-liquid separation equipment. It adopts mechanical and electrical integrated design and manufacture. It has reasonable structure and simple and convenient operation; it can realize filter plate compression, pressure retention, and filter plate loosening. Wait for each process. The filter chamber is composed of a box plate, a filter frame or a box plate arrangement. Under the pressure of the feed pump, the slurry is sent into the filter chamber, and the solid and liquid are separated through the filter medium.

The filter mechanism is composed of a filter plate, a filter frame, a filter cloth, and a press diaphragm. The two sides of the filter plate are covered by filter cloth. When a press diaphragm is required, a set of filter plates consists of a diaphragm plate and a side plate.

The geographical location of a concentrator in Henan is relatively remote, the plant area is large, and the processing capacity is large, but the power supply is insufficient, and the solid-liquid separation often has problems. For this reason, Xinhai specially added frequency converters to the program-controlled automatic hydraulic filter press With the stable current, the solid-liquid separation effect is significantly improved, and the processing capacity is also increased by 11% compared with the previous filter press.

| Model | Filter area (M2) | Filter room Quantity | Filter plate specifications (MM) | Filter cake thickness (MM) | Filter chamber volume (M3) | Filter pressure (MPA) | Dimensions (MM) | Motor power (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| XM/AZ 20/800U | 20 | 20 | 800×800×60 | 30 | 0.287 | 0.5~1.6 | 3500×1350×1160 | 2.2 | 2750 |

| XM/AZ 30/800U | 30 | 30 | 0.453 | 4110×1350×1160 | 3130 | ||||

| XM/AZ 40/800U | 40 | 40 | 0.605 | 4720×1350×1160 | 3420 | ||||

| XM/AZ 50/800U | 50 | 50 | 0.756 | 5330×1350×1160 | 3700 | ||||

| XM/AZ 60/800U | 60 | 60 | 0.907 | 5940×1350×1160 | 4110 | ||||

| XM/AZ 70/800U | 70 | 70 | 1.059 | 6550×1350×1160 | 4400 | ||||

| XM/AZ 80/800U | 80 | 80 | 1.21 | 7160×1350×1160 | 4740 | ||||

| XM/AZ 40/900U | 40 | 32 | 900×900×60 | 30 | 0.59 | 0.5~1.6 | 4230×1480×1280 | 2.2 | 4500 |

| XM/AZ 50/900U | 50 | 40 | 0.75 | 4720×1480×1280 | 4800 | ||||

| XM/AZ 60/900U | 60 | 47 | 0.88 | 5150×1480×1280 | 5100 | ||||

| XM/AZ 70/900U | 70 | 63 | 1.19 | 6120×1480×1280 | 5700 | ||||

| XM/AZ 60/1000U | 60 | 38 | 1000×1000×60 | 30 | 0.9 | 0.5~1.6 | 5450×1560×1360 | 2.2 | 7080 |

| XM/AZ 80/1000U | 80 | 50 | 1.19 | 6180×1560×1360 | 7830 | ||||

| XM/AZ 100/1000U | 100 | 62 | 1.48 | 6910×1560×1360 | 8680 | ||||

| XM/AZ 120/1000U | 120 | 75 | 1.8 | 7710×1560×1360 | 9250 | ||||

| XM/AZ 125/1250U | 120 | 46 | 1250×1250×65 | 32 | 1.9 | 0.5~1.6 | 6500×1770×1620 | 4 | 10900 |

| XM/AZ 150/1250U | 150 | 58 | 2.41 | 7290×1770×1620 | 11800 | ||||

| XM/AZ 180/1250U | 180 | 69 | 2.88 | 8020×1770×1620 | 12700 | ||||

| XM/AZ 200/1250U | 200 | 77 | 3.22 | 8550×1770×1620 | 13300 | ||||

| XM/AZ 220/1250U | 220 | 84 | 3.51 | 9010×1770×1620 | 13900 | ||||

| XM/AZ 250/1250U | 250 | 95 | 3.98 | 9740×1770×1620 | 14800 | ||||

| XM/AZ 300/1500U | 300 | 77 | 1500×1500×70 | 32 | 4.76 | 0.5~1.6 | 10040×2400×1800 | 5.5 | 26500 |

| XM/AZ 320/1500U | 320 | 83 | 5.14 | 10460×2400×1800 | 27190 | ||||

| XM/AZ 340/1500U | 340 | 88 | 5.45 | 10820×2400×1800 | 27880 | ||||

| XM/AZ 350/1500U | 350 | 90 | 5.58 | 10960×2400×1800 | 28230 | ||||

| XM/AZ 380/1500U | 380 | 98 | 6.08 | 11530×2400×1800 | 29260 | ||||

| XM/AZ 400/1500U | 400 | 103 | 6.39 | 11880×2400×1800 | 29950 | ||||

| XM/AZ 450/1500U | 450 | 116 | 7.21 | 12810×2400×1800 | 31670 | ||||

| XM/AZ 500/1500U | 500 | 128 | 7.96 | 13660×2400×1800 | 33390 | ||||

| XM/AZ 560/2000U | 560 | 80 | 2000×2000×83 | 40 | 11.16 | 0.5~1.6 | 10600×2900×2450 | 11 | 56500 |

| XM/AZ 600/2000U | 600 | 86 | 12.01 | 12110×2900×2450 | 58000 | ||||

| XM/AZ 630/2000U | 630 | 90 | 12.58 | 12440×2900×2450 | 59000 | ||||

| XM/AZ 670/2000U | 670 | 96 | 13.43 | 12950×2900×2450 | 60500 | ||||

| XM/AZ 710/2000U | 710 | 101 | 14.13 | 13370×2900×2450 | 62000 | ||||

| XM/AZ 750/2000U | 750 | 107 | 14.98 | 13870×2900×2450 | 63300 | ||||

| XM/AZ 800/2000U | 800 | 114 | 15.97 | 14460×2900×2450 | 65200 | ||||

| XM/AZ 850/2000U | 850 | 121 | 16.96 | 15050×2900×2450 | 67000 | ||||

| XM/AZ 900/2000U | 900 | 128 | 17.95 | 15640×2900×2450 | 69000 | ||||

| XM/AZ 950/2000U | 950 | 135 | 18.94 | 16220×2900×2450 | 70600 | ||||

| XM/AZ 1000/2000U | 1000 | 142 | 19.92 | 16810×2900×2450 | 72300 | ||||

| XM/AZ 1060/2000U | 1060 | 151 | 21.2 | 17570×2900×2450 | 74500 | ||||

| XM/AZ 1120/2000U | 1120 | 159 | 22.33 | 18240×2900×2450 | 76800 | ||||

| XM/AZ 1180/2000U | 1180 | 168 | 23.61 | 19000×2900×2450 | 79000 |

Xinhai High Frequency Dewatering Screen is a uniquely designed tailings dewatering screen with large processing capacity and sufficient dewatering.

A ceramic filter which relies on microporous ceramics for vacuum dewatering.

A dewatering equipment that uses the pressure of the slurry pump to make the liquid come out through the filter cloth. It is divided into a box filter press and a plate and frame filter press.

A traditional external filtration type vacuum filter

A vacuum filter with vertical discs consisted of fanning plates