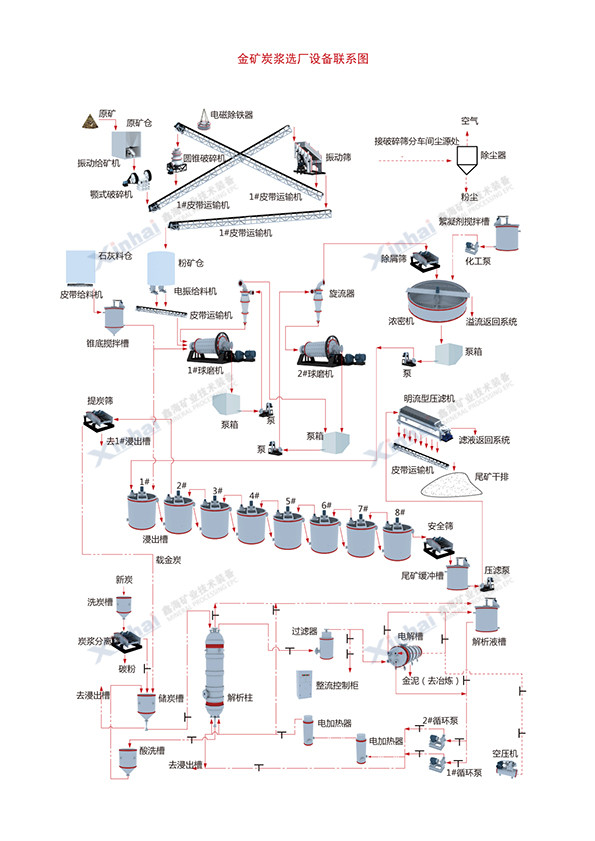

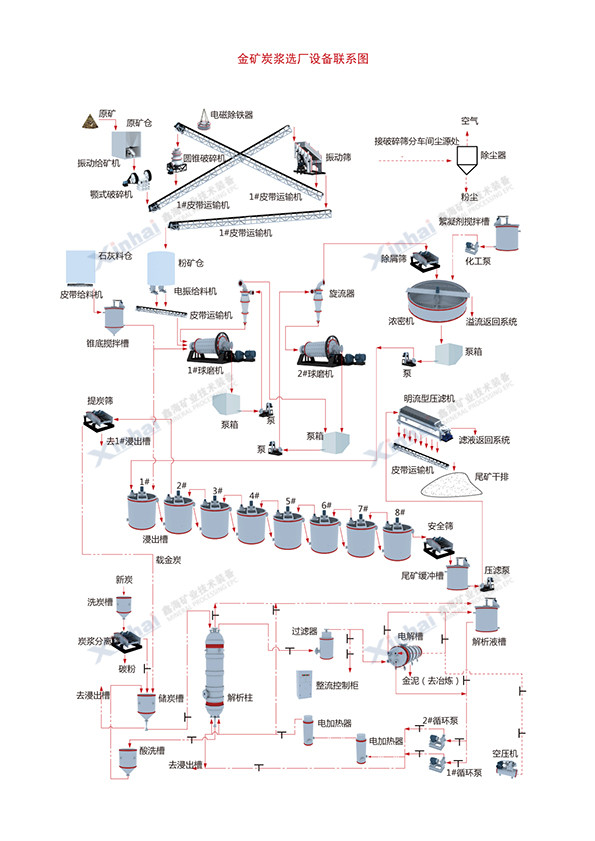

【Process Introduction】:The CIL (Carbon In Leach) leaching process, that is, gold extraction by carbon leaching, is a process in which activated carbon is added to the pulp and the leaching and adsorption of gold are carried out at the same time. It simplifies the cyanidation in the CIP (Carbon In Pulp) process. The two steps of leaching pulp and activated carbon adsorption are one step, which reduces the loss while reducing management costs. Compared with the traditional CCD process, it saves 66% of the investment cost and is the preferred process for modern gold ore beneficiation.

【Application Scope】:The CIL carbon leaching process of gold mines is suitable for the beneficiation of high-grade large-scale gold mines and gold mines with high associated silver and copper content. Compared with the carbon slurry method and traditional methods, the use of this method can obtain significant economic benefits. For small gold mines, Xinhai gold concentrate flotation process is recommended.

The flotation of gold minerals generally adopts a one-stage grinding-flotation process, and a staged grinding-flotation process can be adopted for ores with uneven particle size in Khenpo. A stage of grinding-flotation-flotation process is generally adopted in my country to realize the enrichment of useful minerals.

1. After the crushing and grinding stage of the CIL gold mine process, the slurry is added to 9 Xinhai high-efficiency cyanide leaching tanks arranged in a stepped arrangement. The 7 leaching tanks were cyanided and activated carbon was added for countercurrent adsorption. Compared with the CIP gold mining process and other traditional processes, the Xinhai CIL gold mining process greatly shortens the cyanidation operation time and reduces the backlog of gold in the detention process, with a monthly processing capacity of 100,000 tons of 7.5g/t Take the gold cyanide plant as an example. Compared with the CIP carbon slurry method, the CIL carbon leaching method saves US$486,000 in investment costs, reduces the backlog of gold in production by US$201,700, and deducts the additional US$12,600 in activated carbon costs in the process. And early recovery of funds of 675,100 US dollars.

2. In the process of adding activated carbon, the imported coconut shell activated carbon (small cavity, high activity, wear resistance, and renewable) specially selected by Xinhai Beneficiation Design Institute is added to the slurry, and its ability to absorb gold and silver is used to dissolve and Adsorb gold and silver ions to form gold-loaded carbon. Compared with the traditional process, the dissolution of gold and silver in the process design of Xinhai CIL carbon leaching process is accompanied by the adsorption of activated carbon. The recovery rate of other precious metals has significantly improved economic benefits.

3. Vibration and dewatering equipment is the key equipment for the reverse movement of pulp and carbon. The hydraulic filter press and high-efficiency high-frequency dewatering screen designed by Xinhai Mining Equipment can effectively reduce the continuous pumping and vibrating screen surface of the pulp. The carbon wears out, reduces costs, and facilitates maintenance operations. The central aeration riser used in the mixing process can make the slurry do a small cycle. Compared with other mechanical mixing tanks, Xinhai’s design can reduce the power consumption by 70%, and the solid materials are uniformly suspended, the activated carbon is less abraded, and the gold The recovery rate is high. It is an important equipment in a modern cyanide plant.

4. Xinhai integrated operation desorption electrolysis system uses a mixture of sodium cyanide and sodium hydroxide to desorb and electrolyze gold in gold-loaded carbon at high temperature. First, the wood chips and other debris are removed by the elutriator, and then the Xinhai high-temperature and high-pressure desorption method is used to desorb the gold in a high temperature and high pressure environment of 150 degrees Celsius and 0.5Mpa. This design can remove 99% of the gold in 2-6 hours. Parse it down. The precious liquid obtained by desorption of gold-loaded carbon contains higher concentration of gold and silver cyanide complex ions, while the impurity ions are greatly reduced. This provides an ideal solution for the reduction and recovery of gold from the precious liquid by the electrowinning method. Finally, Xinhai Integrated The chemical operation desorption electrolysis system can safely and economically obtain high-purity solid gold.

The 1200 ton/day gold concentrator project designed by Xinhai Mining for a mining company in Tanzania used the CIL gold extraction process. After the process design, civil engineering, installation and commissioning, it has been put into production. The CIL gold extraction program is finally The available gold leaching rate is 91.5%, which brings considerable economic benefits to the mine owner.

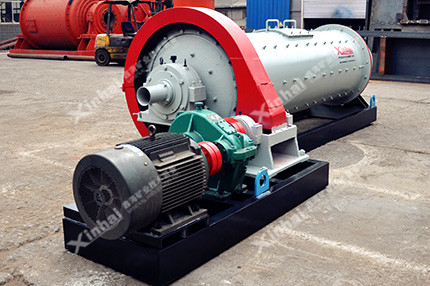

The Energy Saving Ball Mill is a high-efficiency and energy-saving grid-type ball mill that uses rolling bearings.

A dewatering equipment that uses the pressure of the slurry pump to make the liquid come out through the filter cloth. It is divided into a box filter press and a plate and frame filter press.

Xinhai leaching mixing tank is a cyanide leaching mixing equipment designed with reference to American technology.

A slurry pump for conveying pulp with concentration below 65%.

You can fill in your demand information in the form below, and our technical and sales staff will get in touch with you as soon as possible. In order to ensure that your information can be processed in a timely manner, please be sure to fill in your contact number accurately!